2024 Overview - Impreza STI Hatchback

- pleiadesperformanc

- Jul 5, 2025

- 8 min read

The hatchback's story begins from a Facebook marketplace purchase in early 2024, which culminated in a large amount of research and development for Pleiades performance. The car was sold as spares or repair with a misfire, a risky purchase as this could be an easy fix (potentially a coil pack replacement), or a more complex affair!

The previous owner had replaced the coil packs and the misfire was not cured. As a first step, a compression test revealed that the engine was low on compression on all cylinders, with cylinder 2 showing no compression at all. It was then time to remove the cylinder heads from the engine, as this would show the condition of the bores and cylinder heads. The cause of the lack of compression in cylinder 2 was shown straightaway, two exhaust valves were corroded to such an extent that air could pass by the valves when they were shut.

The theory is that the non-parallel fuel line routing caused cylinder 2 to run leaner than the others, causing the valves to get too hot. With the goal to take the hatchback to the Nürburgring in June, time was ticking away to get the engine ready! With some replacement valves ordered, it was time to disassemble the cylinder heads, replace the valves, gaskets and seals, and reassemble the engine ready for the journey! The cylinder heads were skimmed as a precaution against any warpage they might have suffered, and a new set of 1.6mm head gaskets were ordered. It turned out that Supertech valves were installed in the hatchback's engine (which we sell, and highly recommend for a performance engine build), which were the same valves installed in the hillclimb car (see our other blog posts). As the hillclimb car had an intact set of valves, it was decided to install eight valves from the hillclimb car's cylinder heads in the hatchback's heads and give them a small lap to make sure that they would seal during engine operation. After a visual inspection of the valve guides for any corrosion, the valves were fitted, the new valve stem seals were installed, along with new spring seats, and the existing springs, caps, and collets were re-used as they were in good condition. After installing the heads, the refreshed MDX321V turbo, HKS timing belt, and the re-routed fuel lines (so that they provided a parallel feed to the fuel rails!), it was time to refit the engine to the car and use the Link G4X ECU for some datalogging!

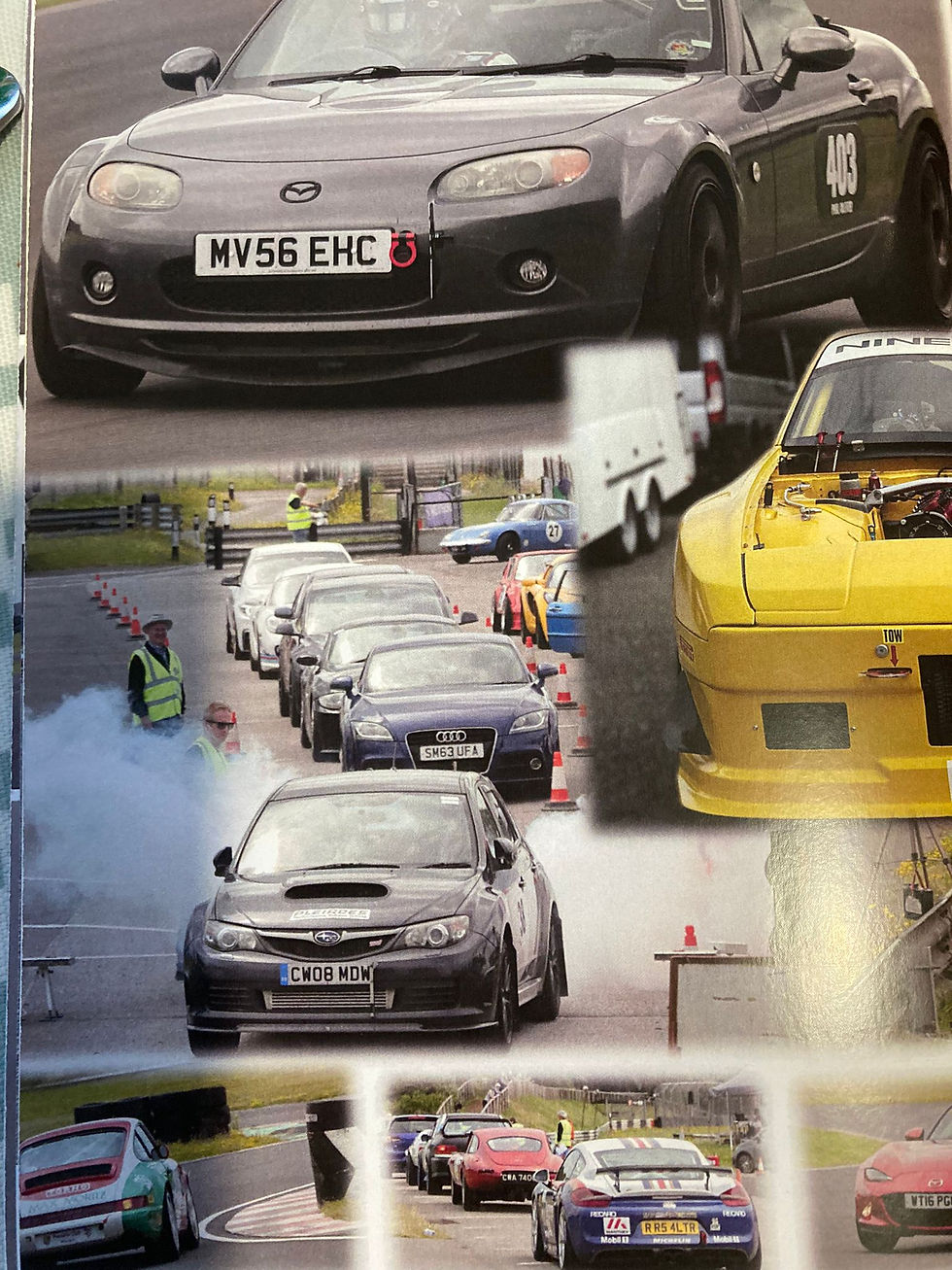

The hatchback's fuelling turned out to be within an acceptable range, and with some small amendments, the addition of launch control and anti-lag switches, and installing both oil pressure and coolant pressure sensors (and mapping their associated rev limiters), the hatchback was ready! The hatchback's first outing was the brilliant Abingdon Car-nival sprint near Oxford, with the car making it to the end of the day with a coolant hose requiring a tighten and the oil needing a top up.

Next, the daunting trip to the Nürburgring was looming, so after a thorough check over the car, and bringing plenty of spares and tools, the big trip began! An issue which became apparent after the first couple of stops on the way to the channel tunnel, was the hatchback' reluctance to start, the cause of which remained a mystery during the trip. After arriving in France, the oil level was checked, with the EJ25 requiring a larger than anticipated amount of oil to be topped up. This became a theme (and a running joke) throughout the trip, with 4.5 litres of coil consumed during the trip of around a 1000 miles.

The weather was a hot 29 degrees during the day, with the hatchback managing four laps over the three days. It was during these laps which the oil pressure protection limiter came into its own, due to a lack of oil pressure at higher revs during the high speed laps. Altogether it was a fun and successful trip, with the hatchback's stiffer chassis found to be much more predictable when pushed hard compared to the earlier Impreza chassis. Some investigation was required to fix the aforementioned problems, with the Castle Combe sprint the hatchback's next event. Prior to the event, an additional datalogging and mapping session was carried out to see if anything seemed to be amiss. When adding some wastegate duty cycle for the MDX321V to make 1.4 bar of boost, the hatchback responded flatly, which should have raised suspicions that something wasn't as it should be. It was then time to head over to the sprint held by Bristol Motor Club at Castle Combe, a fast and open racetrack located in Wlitshire. The practice runs went well for the car, despite seeming down on performance compared to expectations. The decision was then made to use the antilag system mapped on the G4X... This was great fun for the lap, with the hatchback sounding like a group A rally Impreza!

However, some smoke seemed to be blowing from the exhausts upon returning to the paddock. Naively thinking it was just a small oil leak from the turbo's rear seal after getting hot from the antilag, the oil was topped up and the hatchback was sent out for another lap. Unfortunately as the car left the line, the smoke started to billow, and it wasn't long before the car was red flagged and brought back on a recovery truck, our second time on a recovery truck in 2024! Thankfully, the car was trailered to the event, which enabled the journey home to be made safely. It was then time to remove the engine for a thorough inspection.

An unwelcome surprise awaited following the turbo's removal, with the turbine wheel was completely missing! It was eventually found resting on top of the exhaust downpipe's catalytic converter! The turbo also had a large amount of play in the main shaft, and there was evidence that the compressor wheel had been rubbing on the side of the compressor housing, not great at all! Having removed the cylinder heads and peripherals from the engine, the likely cause of the issues was found. The EJ25 had been fitted with a 10mm oil pump, and whilst an oil pressure protection engine RPM limiter was mapped in to reduce engine speed when the oil pressure wasn't up to scratch, it seemed that this wasn't enough to save the turbo. As the cylinder bores were at the rebore limit for an EJ25 (100mm), it was elected to buy a new EJ25 engine block and a set of D25 heads so that the hatchback would have an engine closer to the engine originally installed in the car. The MDX321V was dissassembled and sold, and an IHI VF30 was installed, so that the hatch could develop more low down torque.

An EJ25 Type RA semi-closed deck block was purchased from our friends DL Motorsport (who provide a comprehensive range of Subaru OEM parts at very competitive prices), and we set to work refreshing the D25 cylinder heads, and fitting them to the engine ready for the next hillclimb, which was at one of our favourite venues, Loton Park in Shropshire. After fitting some new valve stem seals and fastening the heads to the engine, it was time to connect all the ancillaries to the engine and run it in.

We were on a tight schedule to get everything done, as the work on the hatchback was finished on the Friday evening, with the drive up to Shrewsbury constituting as the initial running in period, along with the promise to "take it easy" during the hillclimb itself. The journey to shropshire was largely uneventful, with a loose boost hose popping at regular intervals (which handily stopped the car from making much positive boost), and some regular stops were made on the way to check for leaks and untoward noises from the engine.

The Saturday's event was more eventful however, with the engine's continued reluctance to start, regular intervention from the oil pressure limiter, puffs of smoke from the exhaust, all causing some suspicion regarding the engine's integrity. A kind competitor however, had helped to fix the boost pipe from blowing off, which meant that all boost was available - in turn this meant that the promise to "take it easy" was entirely forgotten! The level of chaos escalated substantially on Sunday however, when during the afternoon's first time run, a loud bang was heard from the engine, and upon looking in the rear view mirror a large cloud of smoke was seen. After pulling over at the nearest spot, the engine cut out, with the hatchback spilling around 4 litres of oil on a portion of the track! Needless to say that the organisers and the other competitors weren't too happy about this, but after the awesome volunteer marshalls cleared away the spillage, the event was back underway. This sadly couldn't be said for the hatchback, which had another trip in the recovery truck, and was traillered back to Cardiff for yet more investigation.

The culprit for the chaos were the ringlands within pistons 1 and 2, which had disintegrated and allowed cylinder pressure to escape into the crankcase, causing a loss of oil presure and the turbo's return line to become pressurised and leak. Sadly, this failure resulted in swarf from piston 2's ringlands passing through the exhaust valves and through the turbine, that the cylinder heads needed some work, some new exhaust valves, and a new turbo CHRA had to be purchased.

For extra piece of mind, a new EJ25 Type RA block was purchased. After assembling and putting the new engine in the car, it was time to head out for an initial test drive and to bed in the engine. Another mistake was made here, to bed in the engine at full boost! Another destroyed ringland resulted in a loss of oil pressure and a trailer ride home for the hatchback. Despite the fitment of a new oil pump, the engine was not healthy, meaning that the next hillclimb at Loton park needed to be competed in a completely standard Golf TDI!

It was then time to revisit the hatchback. Another ringland failure in piston 2 was found, mercifully the failure had only lightly scored the bore, with no swarf passing through the exhaust. At the time, the running in procedure was believed to be the cause's fault, as in both prior occasions (to save time) it was decided to run the engine in hard over a shorter amount of miles, as opposed to the 1000 miles recommended by Subaru.

Therefore, the decision was made to rebore the engine to accommodate the 99.75mm Type RA pistons, to deck the block, and to source a set of twin AVCS heads. Roland Alsop machining were to the rescue as usual, and following the machining work, checking the piston ring gaps, fitting the new pistons, refreshing the heads, the hatchback was yet again back in action, with a gentle running in procedure undertaken in accordance with Subaru guidelines. The hatchback's reluctance to start was still apparent, but all else seemed well during the engine's running in period. It was then time for the final sprint event of the year in Castle Combe, and with the hillclimb car's engine not yet ready, it was time for the hatchback to redeem itself during this event.

With the running in completed, the boost was ramped up to 1.2 bar from 0.7 bar of wastegate pressure on the Friday before the event. With rain falling the night before the event, hopes were high of a good result on the Saturday. Unfortunately, after the practice runs on the Saturday, suspicions arose that all wasn't all well with the EJ25 after turning up the boost, with the oil catch can filling up quickly, and the oil pressure limiter activating whilst cornering.

To avoid yet another trip on the recovery truck, it was decided to abandon the event, and to trailer the car back to base. Assembling the hillclimb car's engine took over for the rest of 2024, with the hatchback's development set to continue in 2025...

Comments